REFRACTORY FOR CEMENT INDUSTRY BY TRL KROSAKI

Furmats offers complete range of refractory bricks and castables for Cement Industry Applications.

We have entire ranges of High Alumina (HA) Bricks, Basic Bricks, Monolithics including High Alumina Castables, Low Cement (LC) Castables, Silicon Carbide (SiC) Castables to serve the critical applications of Cement plants, including Cement Kiln, Burner Pipe, Bull Nose, Tip Casting, Kiln Inlet, Cooler apart from Preheater, Cyclone, Calciner, Tertiary Air Duct (TAD).

TRL KROSAKI's REFRACTORIES FOR CEMENT PLANTS

Pre-Heater

Key Concerns

Gas-solid heat transfer (gas/ solids/ walls), particle laden turbulent flow, losses.

Calciner

Key Concerns

Turbulent gas phase/ coal combustion, calcination, heat transfer (gas/ solid/ walls), losses.

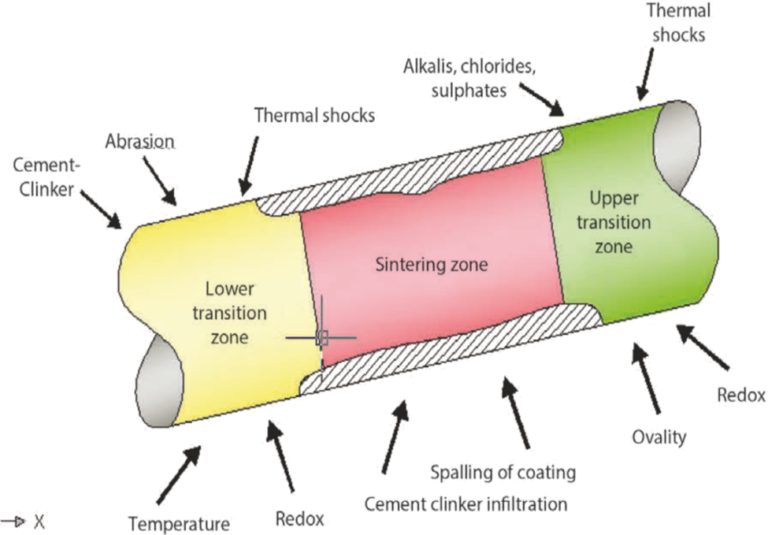

Rotary Kiln

Key Concerns

Coal/ gas phase comb, bed height variation, clinker formation, melting/ solidification, coating formation, losses.

Clinker Cooler

Key Concerns

Gas-solid heat transfer, temperature gradients in clinker bed region.

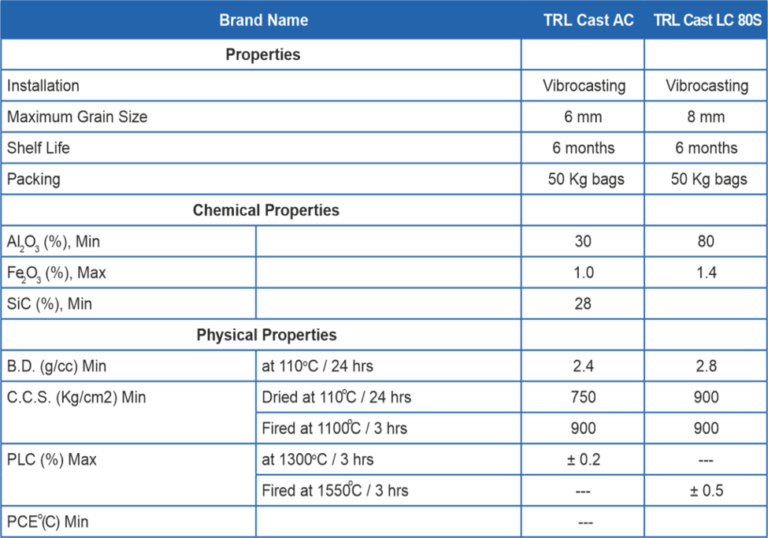

MONOLITHICS

Dense Castables

TRL Krosaki is having all ranges of dense castables starting from 45% to 90% Alumina. The products are specially designed for respective application area.

Low Cement Castables

TRL Krosaki is having all ranges of dense castables starting from 45% to 90% Alumina. The products are made from indigenous and imported raw materials based on application requirement.

BRICKS

Fire Clay Bricks

Furmats offers wide range of fire clay bricks from 30% to 50% Alumina being used in cement industry. The grades are characterized by their excellent resistance to alkali’s & sulfate, high strength and high spalling & abrasion resistance.

High Alumina Bricks

Our High Alumina Bricks from TRL Krosaki fro cement industry are generally ranging from 50% to 85% Alumina. The bricks are having good wear & spalling resistance combine with excellent resistance to alkali & sulphate.

Chemically Bonded Bricks

We offer from TRL Krosaki specially designed chemically bonded bricks for usage in burning & transition zone of Kiln.

Semi Insulating Bricks

TRL Krosaki has a specially designed semi insulating bricks (TRL SIF) for kiln calcination and TAD. This is chemically bonded, high strength, low thermally conductive bricks for increasing the thermal efficiency of the operation.

Magnesia-Alumina Spinel Bricks

TRL Krosaki is equipped with excellent Magnesia-Alumina spinel bricks tailor made for application in burning zone and transition zone. Furmats offers these bricks which are having high thermal shock resistance, elevated thermo-elasticity and resistant to chemical reaction & corrosion.

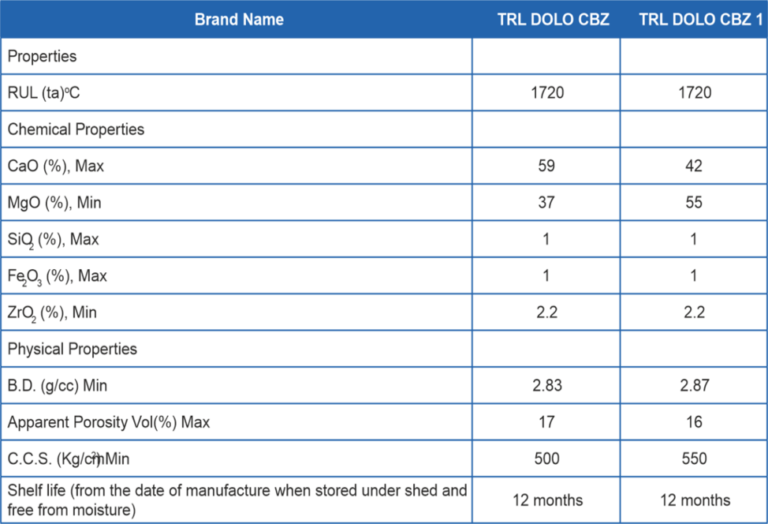

Dolomite Bricks

TRL Krosaki Offers Magnesia enriched Dolomite Bricks for application in burning zone and transition zone. These bricks are highly resistant to chemical corrosion and thermal shock.

Special Chemically Bonded Bricks - TRL PS1, TRL PS2, TRL 60A

Application Area

Special Features

- The lower impurity levels (CaO, K2O, Na2O, and Fe2O3)

- The chemical bonding enhances the thermal shock resistance property

- Excellent alkali resistance property due to following reasons – The lower porosity reduces the permeability of alkali vapours. The chemical bonding reacts with alkali vapours and forms a thin layer of alkali phosphate which prevents further penetration of alkali vapours. The matrix of the brick is rich in Silica which is relatively inert to alkali vapours.

MAGNESIA ENRICHED DOLOMITE BRICK

In some clinker burning system, it has been found either the coating stability in burning zone is relatively lower due to the inherent characteristics and chemical composition of the raw meal or there are increased levels of alkalis, Sulphur and chlorine in the system.

In such cases, particularly when both the parameters are prevalent, a normal dolomite brick, though suitable for stable coating area, are subjected to structural densification due to liquid infiltration, gas penetration through the pores of the bricks and condensation of various salt components at colder region within the brick lining. Field case studies and laboratory findings have shown that this structural densification makes the bricks susceptible to damage by thermocycling and mechanical stresses.

ADVANTAGES

- Reduction in permeability of the brick.

- Protection of free lime surfaces of dolomite grains against direct contact with SO3, Cl2 and Co2.

- Though use of denser variety of dolomite bricks showed the improvement by increasing the life by 50%, purer variety of magnesia enrichment with dolomite yielded further encouraging results where the MgO was solely concentrated in the brick matrix.

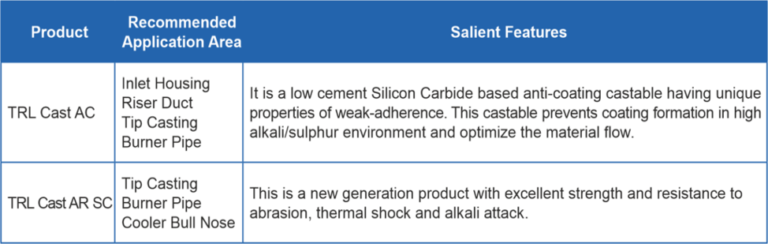

SPECIAL CASTABLES FOR CEMENT INDUSTRY

SPECIFICATION

- Above products are not exclusive. TRL Krosaki is able to manufacture any kind of customized product.

- 95% will be below the maximum grain size mentioned above.

PRODUCT SPECIFICATION

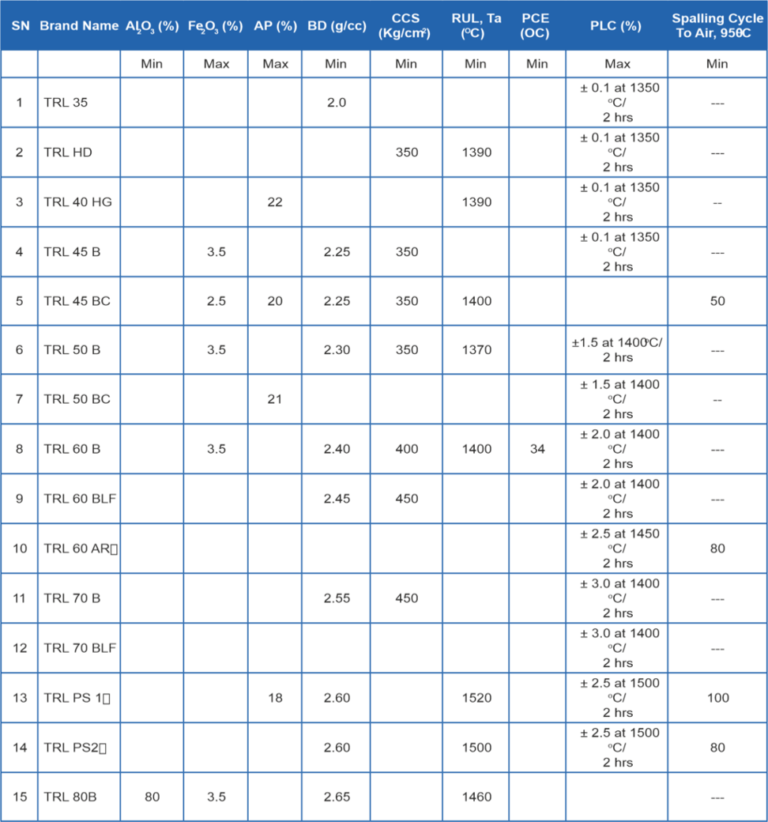

HIGH ALUMINA BRICKS

- These products are not exclusive. TRL Krosaki enables to manufacture any kind of customized product.

- Size Tolerance: ± 1.5% or ± 2 mm whichever is higher * Chemically bonded bricks

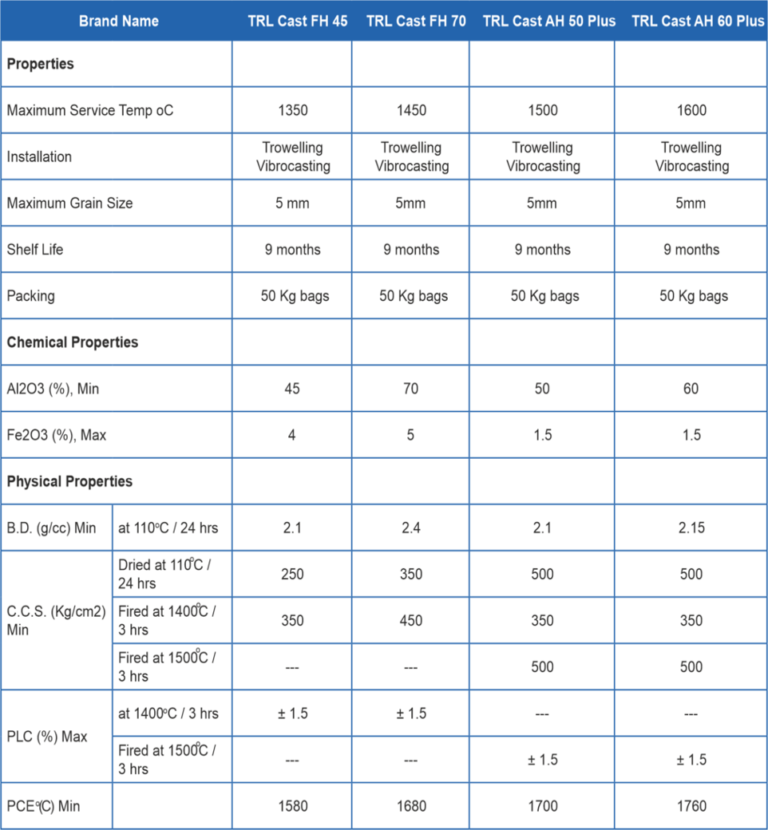

DENSE CASTABLES

- Above products are not exclusive. TRL Krosaki enables to manufacture any kind of customized product.

- 95% will be below the maximum grain size mentioned above.

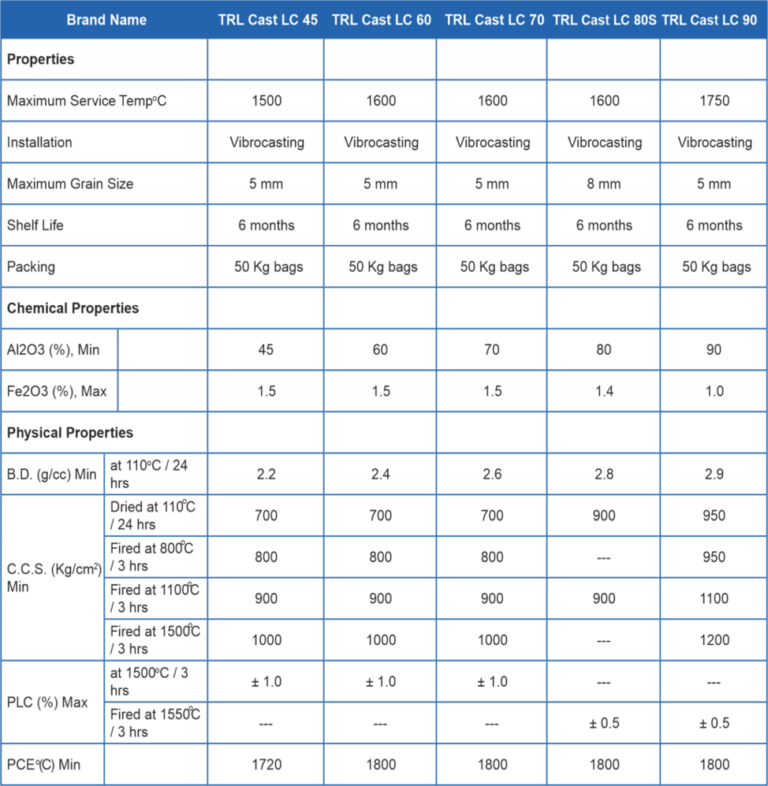

LOW CEMENT CASTABLES

- Above products are not exclusive. TRL Krosaki enables to manufacture any kind of customized product.

- 95% will be below the maximum grain size mentioned above.

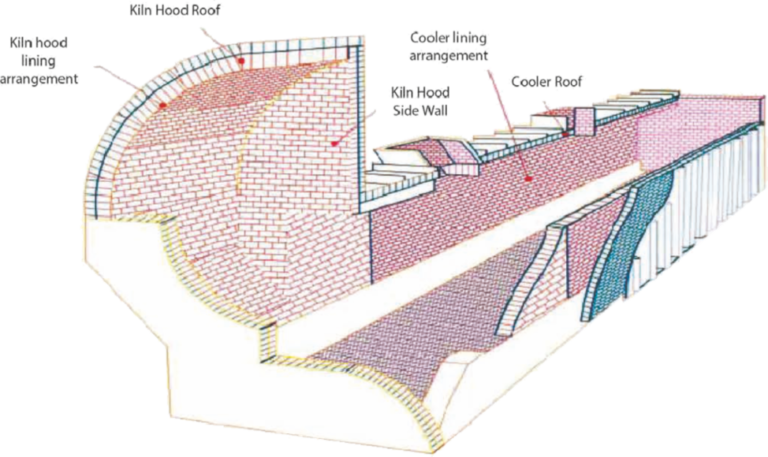

REFRACTORIES LINING PATTERN IN KILN HOOD AND COOLER

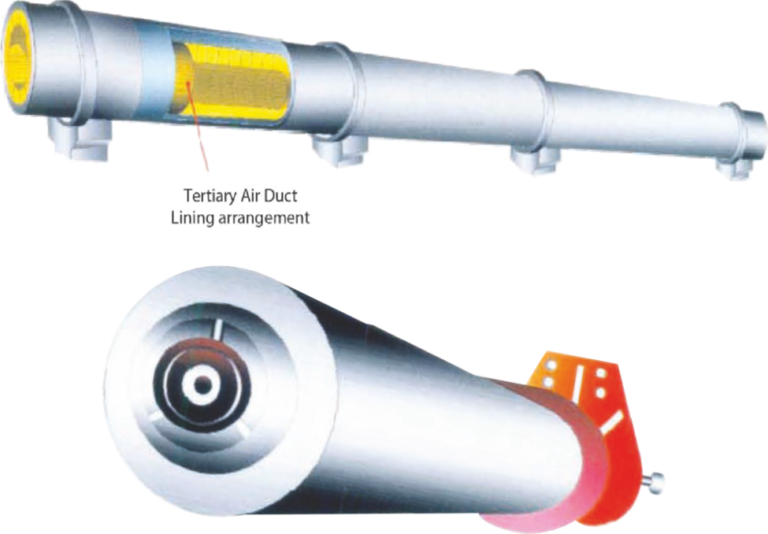

REFRACTORIES LINING PATTERN IN TERTIARY AIR DUCT AND BURNER PIPE

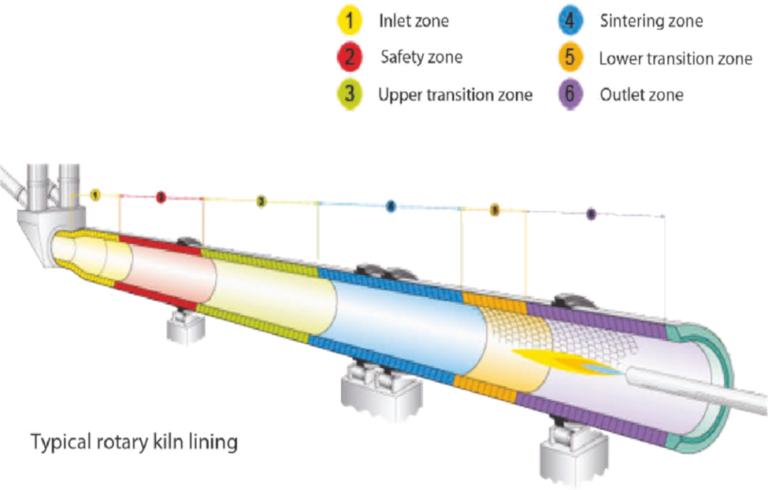

REFRACTORIES LINING PATTERN FOR CEMENT ROTARY KILN

STRESS MECHANISM CEMENT ROTARY KILN